304 316 316L Nickel Alloy or Carbon Steel Construction. August 01 11 1 INTRODUCTION 11 General The storage of granular solids in bulk represents an important stage in the production of many substances derived in raw material form and requiring subsequent processing.

Limits Of Silo Design Codes Practice Periodical On Structural Design And Construction Vol 20 No 2

Usually the distance between two silos needs to be more than 500mm.

. Action Assessment Classes Class Description 3 10000 tonne capacity or 1000 tonne capacity if. In the year 1974 the revision was adopted to design silo for storing all kinds of materials in addition to food grains. 02 Bins are known as silos if they have circular or polygonal shape in plan.

1420 East 4th Street Tulsa Oklahoma 74120 United States. Design codes for metal structures take advantage of the significant progress made in the field. First and foremost are the building codes the International Building Code or IBC that will determine the wind and seismic factors used in the design of the silo itself.

Spent Fuel in Aktau Kazakhstan. Regardless of how you design the silo structure you will need to know the wind loads and seismic loads present on that silo before you can even begin. A brief description of each code and its limitations is provided and common.

I am evaluating a three existing silos. Argons design consisted of a carbon steel cylinder approximately 16 ft long 18 in. Beyond the material factors the existing silo design codes such as BS EN 1991-42006 Australian Standard AS 3774-1996 and American Society of Agricultural Engineers ANSIASAE EP433.

Bins designed for mass flow and funnel flow. Although the study indicated that the. List of ASCEACIAASHTOAISC Codes.

By documenting standard practices the CISC Code of Standard Practice aims to provide guidance on current practices in the Canadian structural steel fabrication and erection industry and its clients. Steel silo design code To use simply stick with your nails we like to keep them at the base of our nail beds and established with distinct topcoat. Considering the requirements of structural design for food grain storage bins silos.

Design criteria and IS9178-PART-III. Guide to the Use of the Wind Load Provisions of ASCE 7-02. The various expressions for the determination of effective width of elements and for the allowable design stresses and other have been given in SI.

ENGLISH Everything that doesnt fit below. This book was not very easy to find out of print. They will draft several plans and select the most appropriate one after comparison.

Our Over 40000 manuals and Ebooks is the reason why customers keep coming backIf you need a steel silo design manual you can download them in pdf format from our websiteBasic file format that can be downloaded and read on numerous devices. Design and Construction of Frost-Protected Shallow Foundation FPSF ASCE 7-02. The Structural Design of Steel Bins and Silos.

This book which contains all the invited general reports and selected papers presented at the Third International Conference on Coupled Instabilities in Metal Structures CIMS 2000 should. Two silos of the exact same size and used for. Canadian Institute of Steel Construction.

Values of hydraulic radius R for hoppers For surcharge calculations Silo Silo Silo Silo Hopper Condition Type A Type B Type C Type D Initial Di 4 Di 4 Da 4 47 L xB L B a 2 a Conical Mass flow D 4 D 4 i c Dc 4 Dc 4 Dc 4 Funnel flow Di 4 Dc 4 Dc 4 Dc 4 Dc 4 L xB L B a Initial Da 4 Da 4 Di 4 2 a Square Mass flow Da 4 Db 4 Db 2 4 Db. The latest edition of the Code can be found on the CISC website wwwcisc-iccaca. Layout Design of Steel Silos.

File Type PDF Steel Silo Design Example. Indian code of practice criteria for design of steel bins for storage of bulk materials IS9178-PART-I General requirements and assessment of loads IS9178-PART-II. The physical nature of the materials to be stored in the bins are taken into account and the code classified the stored materials as.

Steel Silo Design Code. X Eccentric discharge with eccentricity greater than 25 of cylinder diameter x Squat silo cylinder height between 40 and 100 of cylinder diameter with top surface eccentricity greater than 25 of cylinder diameter 2 All silos not in Class 1 or 3 1 Capacity. Specific principles and application rules for silos Distinction between Silos supported on the ground Elevated silos Response of the particulate solid Additional positive or negative pressure on the wall Pressure depending on the acceleration along the height Behaviour factor q 15 for silos supported on the ground.

Indian Code of practice for silos for grain storage IS5503PART- I-1969. Outside diameter and 0375 in. Minimum Design Loads for Buildings and Other Structures.

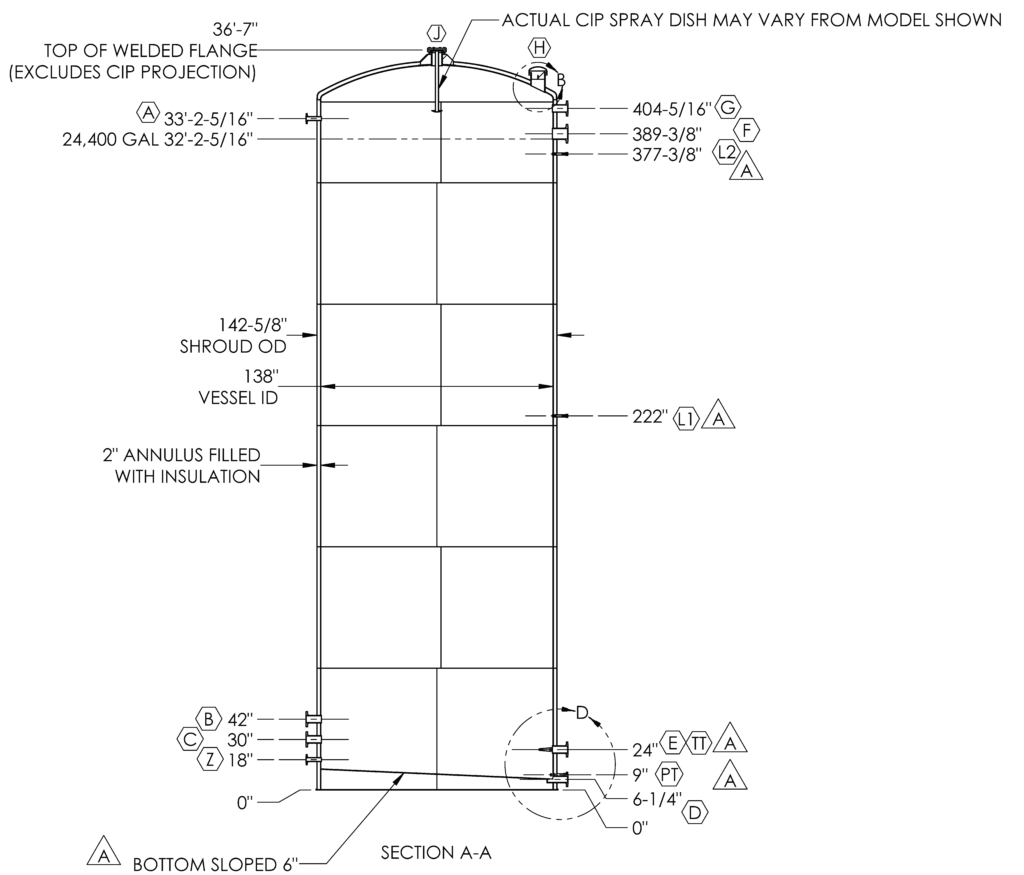

Features of Our Stainless Steel Vertical Silos Vertical Design Shell Options. An eye-catching style has never been simpler. The design of light gauge steel structural members in general building construction has been revised as per code of IS.

The carbon steel silo was protected from corrosion by a duplex coating system consisting of zinc and epoxy. The Powder Flow Function the wall friction angle the static angle of internal friction. 03 The functions of bins as storage structures are very important in power.

The following data must be known in order to calculate the silo. The design of bins and silos to store bulk solids involves bulk. You can revise this using your PC MAC tablet eBook reader or smartphone.

Flat Sloped or Conical. Sanitary Finish Manaway Options. The best references I have found are Design of Steel Bins for Stroage of Bulk Solids by Charles Gaylord.

Units along with the. These bulk solids bins hoppers silos and blenders generally meet the philosophy and requirements of Section VIII Division 1 of the ASME Boiler and Pressure Vessel Code henceforth referred to as the Code. Every function or a formula is explained with typical Civil Engineering example.

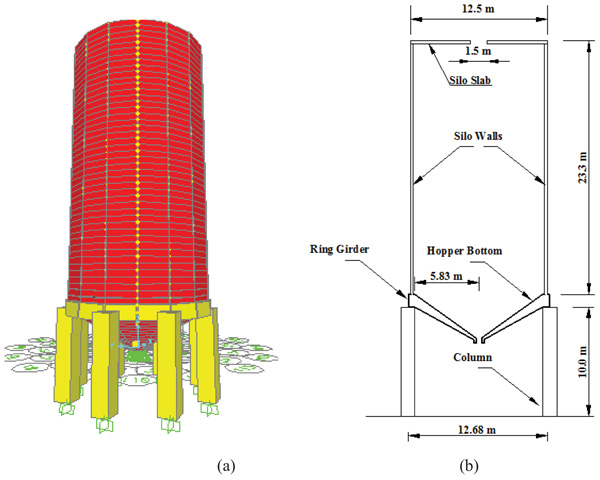

In the layout design of steel silos designers need to consider the construction technology terrain engineering geology total investment and many otehr elements. Numerous codes and standards specify means to calculate material-induced loads that are needed to design silos. When square or rectangular in plan they are known as bunkers.

In this standard bin shall mean both silos and bunkers unless otherwise stated. The three most commonly used of such codes do not provide users with consistent information and many common silo design conditions are not covered. Top Entry or Shell Access.

ASME Code Section I und IV - Dampf- und Heizkessel ASME Code Section VIII - Druckbehälter ASME Code Section III - Nuklearanlagen ASME Code Section V - Zerstörungsfreies Prüfen ASME Code Section IX - Schweißen ASME Code und die Druckgeräterichtlinie DGRL 201468EU. This one can be purchased in Kindle format or Mobipocket. STEP 1 - Get information on the powder.

However Code inspection and stamping are not required. Guide for the Economic Design of Circular Metal Silos by JM. August 01 Table 41.

Knowing the characteristics of the product to discharge is the 1st and mandatory step to properly design a hopper.

Building Codes And Bulk Storage Silo Design Powderbulksolids Com

Bulkmatic Silos Ssv Bulk Storage Bss Silos Valve Safety Valve

Building Codes And Bulk Storage Silo Design Powderbulksolids Com

A Simplified Approach For Analysis And Design Of Reinforced Concrete Circular Silos And Bunkers

Design Your Silos With Fea It Pays Enterfea

Stainless Steel Silos For Sale For Grain Water And More

Steel Silo Design Silo Storage Solutions From Professioanl Engineers

0 comments

Post a Comment